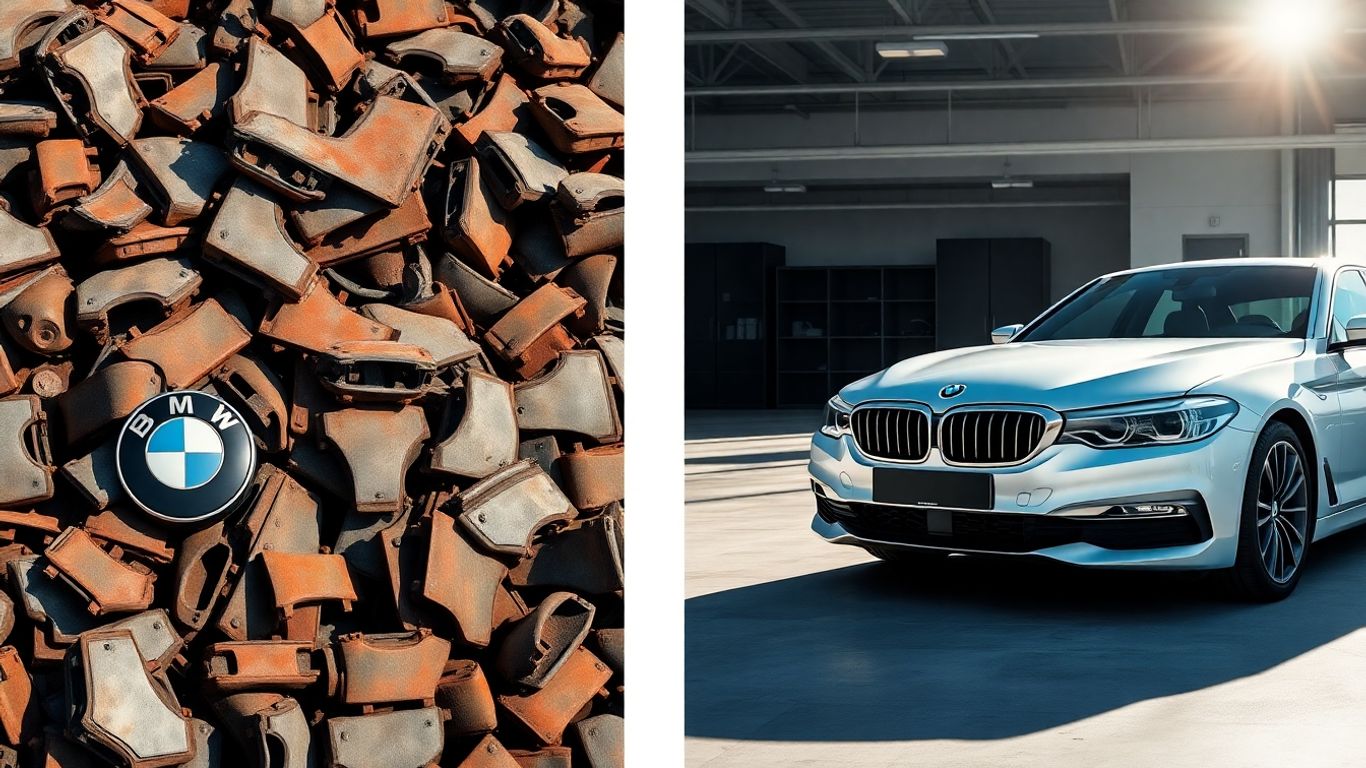

It’s amazing what can happen when a company decides to really focus on waste. We’re looking at the BMW wreckers success story, which shows how a big operation can shift its thinking. They went from just dealing with old car parts to becoming a leader in recycling. This wasn’t an overnight thing, but a steady effort to reduce what goes to the trash. It’s a great example for any business wanting to be greener and save money at the same time.

Key Takeaways

- BMW’s journey to zero landfill started with workshops and inspiration from other companies, leading to a program focused on reducing waste per vehicle.

- Innovative recycling methods, like turning paint shop rags into insulation, significantly cut costs and waste, saving BMW around $60,000 annually.

- A dedicated ‘Green Team’ and a step-by-step audit process are vital for achieving and maintaining zero landfill status across different facility areas.

- On-site composting of cafe waste and using it for landscaping reduces weekly landfill contributions and positively impacts the local community.

- The BMW wreckers success story highlights that a strong company champion and a phased approach are key to tackling large environmental goals like zero landfill.

The Genesis Of A BMW Wreckers Success Story

From Landfill Aspirations to Zero Waste Goals

It might sound a bit odd, but the whole journey towards becoming a zero-landfill operation for BMW really kicked off around late 2009 and early 2010. Before that, the idea of aiming for zero waste wasn’t really on the table. It was more about managing what was already there. But then, some folks from BMW went to workshops about zero landfill, hosted by a group called the Green Manufacturer Network. They heard about other companies doing cool things to cut down on trash, and it got them thinking. This sparked the idea that maybe, just maybe, they could do it too. It wasn’t about aiming for perfection right away, but about starting to chip away at the waste problem, with the big goal of eventually sending nothing to the landfill.

The Spark of Inspiration: Learning from Industry Leaders

Those zero landfill workshops were a real eye-opener. Hearing success stories from other manufacturers really lit a fire. It showed that what seemed like an impossible goal was actually achievable. People presented their methods, their wins, and even their struggles. This wasn’t just theoretical stuff; it was real-world examples of companies making a difference. It made BMW think, "Hey, if they can do it, why can’t we?" It was that shared experience and the visible results of others that provided the push and the blueprint to start their own program.

Laying the Foundation: Early Recycling Initiatives

So, after getting inspired, BMW didn’t just jump straight into the deep end. They started small, building on what was already happening. Recycling paper, glass, and aluminum was pretty standard practice, but they knew they needed to do more. The real push to reduce landfill waste began in May 2010. This wasn’t just about throwing things in different bins; it involved getting everyone involved. They started looking at how much waste was produced per car, which was around 20 pounds back in 2009. They also began working with their suppliers, trying to find ways to reduce packaging materials or reuse what they got. It was about setting up the basic systems and getting people thinking about waste in a new way, even if the big zero-landfill goal was still a ways off.

Implementing Innovative Recycling Strategies

The Power of ‘Dumpster Diving’ and Employee Education

So, how do you get everyone on board with recycling? One pretty direct way is what they call ‘dumpster diving.’ It sounds a bit messy, but it’s actually a smart way to show people exactly what’s being thrown away. By digging through the trash (with gloves, of course!), employees can see firsthand how much good stuff is being tossed out that could have been reused or recycled. This hands-on approach really drives home the point about waste. It’s not just about telling people to recycle; it’s about showing them why it matters and what they’re actually throwing away. Plus, asking employees for their ideas on how to cut down on waste and improve recycling is a big deal. When people feel heard and see their suggestions put into action, they get more invested in the whole process. It turns a chore into a shared goal.

Supplier Collaboration for Material Reduction

It’s not just about what happens inside the plant; it’s also about working with the folks who supply the parts and materials. Think about packaging. Instead of just accepting whatever comes in, companies are working with their suppliers to reduce the amount of packaging used in the first place. Sometimes, this means redesigning the packaging to be smaller or lighter. Other times, it involves setting up systems to reuse packaging materials. For example, some companies have managed to reuse sturdy shipping containers or foam inserts multiple times, sending them back and forth between suppliers and the plant. This not only cuts down on waste but also saves a good chunk of money. It’s a partnership approach where both sides benefit from being more mindful about materials.

Transforming Paint Shop Rags into Insulation

Here’s a really neat example of creative recycling. In the paint shops, there are a lot of rags used to clean up excess paint or sealants. Normally, these oily, chemical-soaked rags would just be trash. But instead of tossing them, they’re sent off to a special facility. There, these rags are shredded up and turned into a material that’s used for insulation inside vehicles. It’s a clever way to give waste a second life and avoid sending it to the landfill. This kind of thinking transforms what was once considered garbage into a useful component, saving the company a pretty penny in the process – we’re talking tens of thousands of dollars saved annually just from this one practice.

The key is to look at everything that leaves the production line not as waste, but as a resource that’s just temporarily out of place. This shift in perspective is what drives real change.

| Material Type | Annual Savings | Notes |

|---|---|---|

| Paint Rags | $60,000 | Used for interior insulation |

| Reused Packaging | $1.3 Million | Styrofoam for transmissions/engines |

| Brass Washers | N/A | Returned to suppliers |

| Protective Caps | N/A | Returned to suppliers |

Achieving Zero Landfill Status

Getting to a point where absolutely nothing goes to the landfill wasn’t an overnight thing. It took a structured approach, starting with a dedicated team and a clear plan.

Establishing a Dedicated Green Team

First off, BMW put together a "Green Team." This wasn’t just a few people; it included folks from all over the assembly plant. Their job was to really focus on finding ways to cut down on waste and figure out what could be recycled or reused. Having people from different departments involved meant they could see problems and solutions from all angles. It’s like having a bunch of eyes and ears looking out for waste reduction opportunities everywhere.

A Phased Approach to Waste Elimination

BMW didn’t try to do everything at once. They broke it down into smaller steps. The idea was to get certain areas of the plant to be zero landfill first, and then expand from there. They called this "eating an elephant one bite at a time." Each area had to prove it could handle its waste properly. This involved sorting everything that was thrown away, figuring out what was what, and making sure it all went to the right place – recycling, reuse, or composting.

It was a pretty detailed process. First, they’d pick "waste champions" in each area, who were basically the go-to people for recycling. Then, they’d sort and categorize all the waste generated in that area. Finally, outside auditors would check daily to see if everything was being sorted correctly. If an area passed a certain number of these checks, they’d get a temporary "zero landfill" status. But they had to keep it up for six months before it was official. This careful, step-by-step method made the big goal feel more manageable.

Sustaining Zero Landfill Through Audits

Once an area hit zero landfill status, the work wasn’t over. They had to keep it that way. Regular audits by a waste management company became the norm. These audits were like a final check to make sure everyone was still following the rules. If all the waste bins in an area were sorted right during a visit, a little green dot would be put on a checklist. After a bunch of these successful checks, the area could keep its zero landfill title. This constant checking helped make sure the changes stuck and that the plant didn’t slip back into old habits. It’s all about keeping that momentum going and making sure the green practices become second nature.

The journey to zero landfill is a marathon, not a sprint. It requires consistent effort, clear communication, and a willingness to adapt. By breaking down the challenge into smaller, achievable goals and involving everyone in the process, even the most ambitious environmental targets can be met.

Beyond Recycling: Comprehensive Waste Management

So, we’ve talked a lot about recycling, right? But what happens when you’ve pretty much recycled everything you can? That’s where this next part comes in. It’s all about looking at the bigger picture of waste, not just the stuff that goes in the blue bin.

Composting On-Site for Landscaping Needs

Think about all the food scraps from the break room or cafeteria. Instead of just tossing that into the trash, BMW Wreckers started a composting program. It’s pretty neat, actually. All that organic stuff gets broken down right there on-site. And guess what? That compost then gets used to keep the company grounds looking nice. It’s a simple idea, but it really cuts down on what’s heading to the landfill. We’re talking about hundreds of pounds of waste diverted each week, just from food scraps alone. It’s a win-win: less trash and free fertilizer for the landscaping.

Addressing Non-Recyclable Waste Streams

Now, let’s be real. Not everything can be recycled or composted. There’s always going to be that leftover 10-15% of waste that’s a bit trickier. For BMW Wreckers, this meant looking at things like wastewater treatment sludge, which is a big one. They’re exploring options like waste-to-energy programs. This means that the stuff that can’t be recycled gets sent to special facilities where it can be burned to create energy. It’s not ideal, but it’s way better than just letting it sit in a landfill. It’s about finding a use for everything, even the stuff that seems like a lost cause.

The key here is to keep looking for solutions. Even when you think you’ve got it all figured out, there’s always something new to learn or a better way to do things. It’s about being persistent and not giving up on those tough waste streams.

The Impact on Local Communities and Businesses

This whole zero-waste thing isn’t just good for the company; it actually has a ripple effect. When a place like BMW Wreckers makes such a big effort to reduce waste, it gets people talking. It inspires the employees, sure, but it also encourages other local businesses to think about their own waste. It shows that being environmentally responsible can actually be a smart business move. Plus, less waste going to landfills means a cleaner environment for everyone in the area. It’s a positive cycle that benefits the whole community, not just the bottom line.

| Waste Stream | Current Status | Future Solution | Savings Potential |

|---|---|---|---|

| Food Scraps | Composted On-Site | N/A | Reduced landfill fees |

| Sludge | Landfill | Waste-to-Energy | Reduced landfill fees, energy generation |

| Textiles (Paint Rags) | Recycled into Insulation | N/A | $60,000 annually |

| Packaging | Reduced & Reused | N/A | $1.3 million annually (example) |

The Financial and Environmental Rewards

Significant Annual Savings from Recycling Practices

It turns out that all that effort in sorting and recycling really adds up. We’ve seen a noticeable drop in our waste disposal costs, which is a nice surprise. Plus, by reusing and repurposing parts, we’re cutting down on the need to buy new ones, saving a good chunk of change there too. It’s not just about being green; it’s about being smart with our money.

| Waste Stream | Annual Savings (Estimated) |

|---|---|

| Metal Scrap | $15,000 |

| Used Tires | $5,000 |

| Reusable Parts | $25,000 |

| Other Recyclables (Plastic, Glass) | $3,000 |

The financial benefits are pretty straightforward. Less trash going to the landfill means lower tipping fees. Finding value in what we used to throw away, like selling scrap metal or refurbishing parts for resale, creates new income streams. It’s a win-win situation that makes good business sense.

Boosting Employee Enthusiasm for Green Manufacturing

Something unexpected happened when we started focusing on recycling: the team got really into it. People started coming up with their own ideas for reducing waste and improving our processes. It’s created a more positive vibe around the workshop, and everyone seems a bit more invested in what we’re doing. It’s cool to see people taking pride in making the business more environmentally friendly.

Corporate Responsibility as a Driving Force

Being a responsible company matters. We’ve found that customers and partners appreciate our commitment to sustainability. It’s not just about following rules; it’s about doing the right thing for the planet and our community. This focus on environmental care has become a big part of our identity and something we’re really proud of.

BMW Wreckers Success Story: A Blueprint for Others

Lessons Learned from BMW’s Zero Landfill Journey

BMW’s path to becoming a zero-landfill operation wasn’t an overnight thing. It started with a real commitment, kind of like deciding you’re actually going to clean out that garage. They began by looking at what other companies were doing, which is smart, right? Why reinvent the wheel? They even had folks attend workshops, which sounds a bit dry, but it’s where the ideas really started to click. The big takeaway here is that it takes a plan and a willingness to get your hands dirty – literally, with those "dumpster diving" sessions to see what’s actually being thrown away. It’s about understanding your waste before you can cut it down.

Inspiring a New Era of Automotive Recycling

What BMW has shown is that being environmentally responsible isn’t just good for the planet; it makes good business sense too. Think about it: less waste means less money spent on disposal fees. Plus, finding new uses for old materials, like turning paint shop rags into insulation, saves a good chunk of change each year. It’s not just about the big savings, though. It seems to make the employees feel better about their work, knowing they’re part of something positive. This kind of initiative can really change how people see manufacturing – it’s not just about making cars, it’s about making them in a smarter, cleaner way.

The Continuous Pursuit of Environmental Excellence

Reaching zero landfill isn’t really an end goal, more like a starting point for ongoing improvement. BMW keeps at it with regular checks and a dedicated team focused on waste. They’re always looking for ways to reduce what’s left, even exploring things like waste-to-energy programs for the stuff that’s really tough to recycle. It shows that once you start down this road, you don’t just stop. You keep looking for better methods, pushing to be even more efficient and cleaner. It’s a cycle of improvement, much like the cars they build, always aiming for the next level of performance and sustainability.

The Road Ahead: More Than Just Parts

So, what’s the big takeaway from all this? It’s pretty clear that the whole idea of ‘junking’ cars is changing. What used to be just scrap metal is now seen as a resource. Companies like BMW, and others we’ve talked about, are showing us that you can actually make good money and do right by the planet at the same time. It’s not just about tossing old parts; it’s about smart recycling, finding new uses for materials, and really thinking about waste. It proves that with a bit of creativity and a solid plan, even the most worn-out vehicle can contribute to a cleaner future and a healthier bottom line. It’s a win-win, really.